How Purified Water Works

Water is one of nature’s renewable resources. However, meeting our growing water needs through the natural process alone is becoming increasingly challenging, especially in the face of drought and climate change. An adequate supply of safe, reliable water is crucial to protecting our future. The purification center has successfully demonstrated our ability to create a safe, reliable, drought resilient addition to our water portfolio, producing as much as 8 million gallons per day of advanced purified water that meets state and federal standards.

The purification center receives secondary-treated wastewater from the San Jose-Santa Clara Regional Wastewater Facility located across the street. The incoming wastewater has undergone two treatment cycles (or about 10 hours of treatment) that help remove 99% of solid impurities in the water. At the purification center, the water undergoes three additional advanced treatment processes that purify the water to drinking water quality. Currently, this water is blended with recycled water to enhance its quality and expand its usage. However, Valley Water is working on expanding purified water reuse to boost our drinking water supply.

These processes are proven in the water treatment industry and are already used around the world to provide safe, drinking water. You can view an interactive World Map to see where people are already drinking advanced purified water.

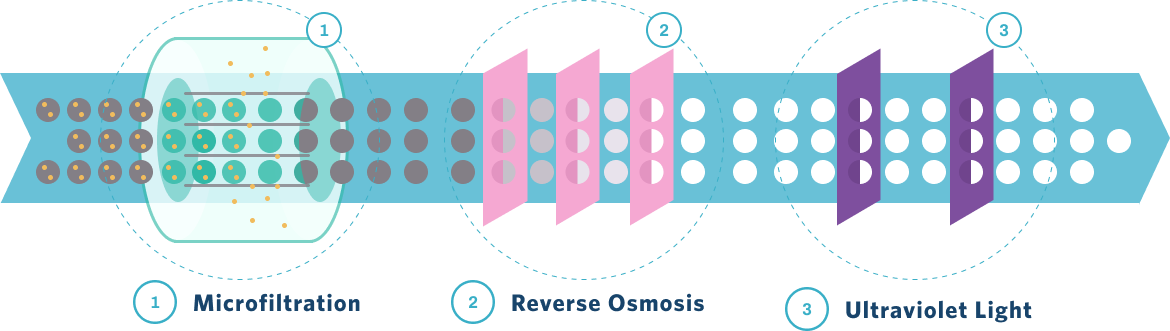

1. Microfiltration

In this process, treated wastewater is pumped through filtration vessels that contain thousands of hollow fibers, similar to straws. The walls of these fibers have very fine pores, only 0.1 micron in diameter or about 300 times smaller than the width of a human hair. As the water flows through the pores into the center of the fibers; solids, bacteria, protozoa and some larger viruses are filtered out.

2. Reverse Osmosis

Reverse Osmosis forces water under high pressure through membrane sheets with pores so small that chemicals the size of water molecules are generally the only substances that can pass through. The process removes viruses, bacteria, pharmaceuticals, large chemicals, and pesticides as well as organic matter.

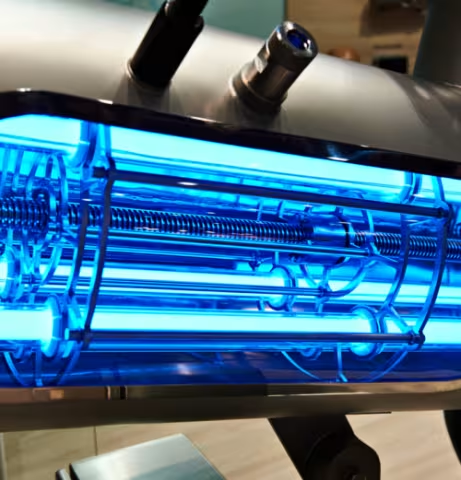

3. Ultraviolet Light

After microfiltration and reverse osmosis, the water is exceptionally clean but as an additional safety measure, the water is sent through chambers that emit ultraviolet light to inactivate any remaining viruses and break down some of the remaining trace contaminants. Ultraviolet light is a powerful disinfection process that produces high-quality water and is highly efficient at destroying pathogens. This technique is also often used to sterilize medical equipment, foods, and fruit juices.

4. Advanced Oxidation

Valley Water is in the process of adding advanced oxidation to our pilot system for research and demonstration purposes. Advanced Oxidation is a process in which trace amounts of hydrogen peroxide is added to the water to reinforce disinfection. Future purification facilities will include this process at full-scale. Valley Water has chosen to implement this process to go above and beyond the required minimum level of treatment mandated by the State Division of Drinking Water regulations for advanced purified water. This will ensure high-quality water that meets drinking quality standards.

Benefits of Purified Water